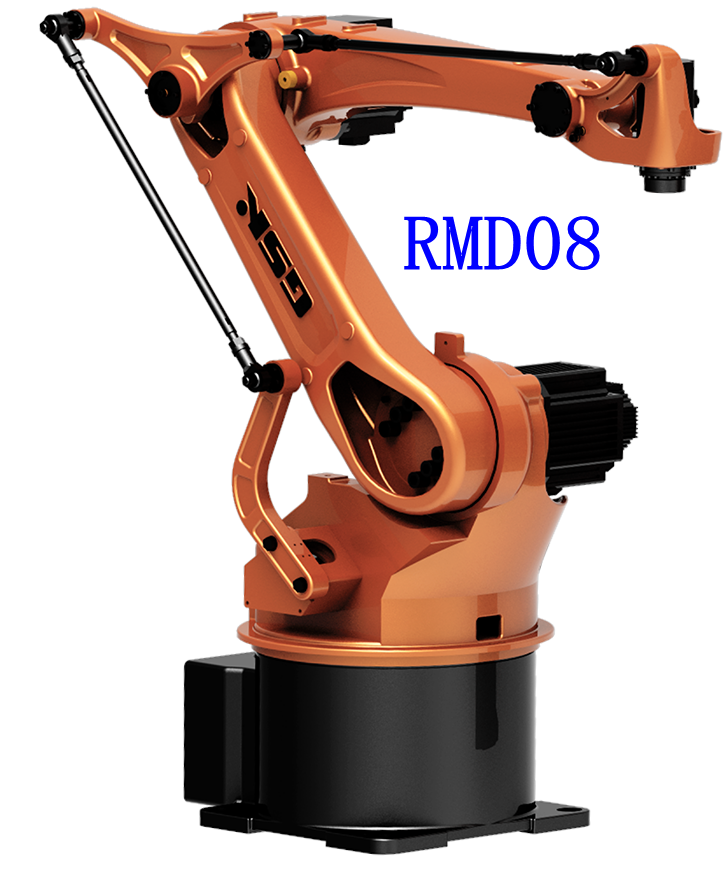

GSK機(jī)器人RMD08自動(dòng)化工業(yè)碼垛拆垛搬運(yùn)上下料機(jī)械手臂

品牌 廣州鉅澤_廣州數(shù)控KOZA_GSK

產(chǎn)地 廣州 訂貨號(hào)KOZA_GSKRMD08

工作范圍1413 關(guān)節(jié)數(shù)量4-6

本體重量180kg 有效負(fù)載8kg

重復(fù)定位精度±0.08mm 數(shù)量10000

可售賣(mài)地 全國(guó) 型號(hào)KOZA_GSKRMD08

廣州鉅澤_廣州數(shù)控_碼垛機(jī)器人KOZA_GSK_WELDING Palletizing ROBOT,質(zhì)保三年!

RMD08,有效負(fù)載8公斤,重復(fù)定位精度±0.08MM,

1.可輕松完成沖壓上下料、拆垛、碼垛、搬運(yùn)等任務(wù);

2.為用戶(hù)提供快速、安全、靈活 定位等全套作業(yè)解決方案。

1)運(yùn)動(dòng)速度快

運(yùn)動(dòng)速度快。沖壓節(jié)拍可高達(dá)14次/分。

2)運(yùn)動(dòng)范圍大

相較運(yùn)動(dòng)范圍在500mm以?xún)?nèi)的傳統(tǒng)擺臂機(jī)器人,RMD08的工作半徑可達(dá)1410mm,可輕松應(yīng)用于沖床中心距2.5m的沖壓場(chǎng)合。

3)性能穩(wěn)定、壽命長(zhǎng)

一二三軸采用RV減速器,比起擺臂機(jī)械手用的諧波減速器,壽命和耐沖擊性可大一倍、穩(wěn)定性、送料精度更高。

4)通用性能佳

①對(duì)設(shè)備噸位、沖床高低無(wú)要求,可多臺(tái)連線。客戶(hù)產(chǎn)線自動(dòng)化升級(jí),無(wú)需跟換機(jī)床設(shè)備,節(jié)省投資50%~60%。

②相對(duì)于擺臂型機(jī)械手,豎直高度的運(yùn)動(dòng)范圍更大,沖壓上下料、碼垛、搬運(yùn)工序。

Rmd08, payload 8kg, repeated positioning accuracy ± 0.08mm,

1. It can easily complete stamping loading and unloading, destacking, palletizing, transportation and other tasks;

2. Provide users with a complete set of operation solutions such as fast, safe, flexible, accurate and positioning.

1) Fast movement

Fast movement. The stamping time can be up to 14 times / min.

2) Wide range of motion

Compared with the traditional swing arm robot, rmd08 has a maximum working radius of 1410mm, which can be easily applied to the punching occasions with a center distance of 2.5m.

3) Stable performance and long service life

RV Reducer is adopted for the first, second and third axles. Compared with the harmonic reducer used for swing arm manipulator, it has double life and impact resistance, higher stability and feeding accuracy.

4) Good general performance

① There is no requirement for the tonnage of equipment and the height of punch, and more than one can be connected. Customer production line automatic upgrade, no need to change machine tools and equipment, saving 50% - 60% investment.

② Compared with the swing arm manipulator, the vertical height has a larger range of motion, stamping, stacking and handling processes.

東莞市海博創(chuàng)智能科技有限公司

專(zhuān)業(yè)生產(chǎn)注塑機(jī)專(zhuān)用機(jī)械手及其他自動(dòng)化設(shè)備丨點(diǎn)焊機(jī)器人丨搬運(yùn)型丨通用 型機(jī)器人丨噴涂機(jī)器人丨為注塑生產(chǎn)工廠提高自動(dòng)生產(chǎn)力丨提高 生產(chǎn)穩(wěn)定 性丨生產(chǎn)效 率和品質(zhì)丨并適當(dāng)減少生產(chǎn)人員丨從而使 注塑生產(chǎn)工廠更具有 市場(chǎng)競(jìng)爭(zhēng)優(yōu)勢(shì)。本公司從產(chǎn)品規(guī)劃設(shè)計(jì)丨 制造丨組裝丨銷(xiāo)售丨 服務(wù)丨綜合 為客戶(hù)提供*的整體自動(dòng)化 解決方案與服務(wù)丨并 廣泛應(yīng)用于電子丨通訊 丨汽車(chē)丨家電等領(lǐng) 域。為塑膠業(yè)界提供 高品質(zhì)丨**率丨價(jià)格合理的自動(dòng) 化產(chǎn)品 。

一般項(xiàng)目:

智能機(jī)器人的研發(fā);

工業(yè)機(jī)器人制造;

工業(yè)機(jī)器人安 裝、維修;工業(yè)機(jī)器人銷(xiāo)售;

智能基礎(chǔ)制造裝備銷(xiāo)售;

智能基礎(chǔ)制造裝備制造;

工業(yè)自

動(dòng)控制系統(tǒng)裝置制造;

工業(yè)自動(dòng)控制系統(tǒng)裝置銷(xiāo)售;

儀器儀表制造;

智能儀

器儀表銷(xiāo)售;

電力電子元器件制造;

電力電子元器件銷(xiāo)售;

普通機(jī)械設(shè)備安

裝服務(wù);

網(wǎng)絡(luò)與信息安全軟件開(kāi)發(fā);

技術(shù)服務(wù)、技術(shù)開(kāi)發(fā)、技術(shù)咨詢(xún)、技術(shù)

交流、技術(shù)轉(zhuǎn)讓、技術(shù)推廣;

貨物進(jìn)出口;技術(shù)進(jìn)出口。